Today, the PLC programmer is usually the last person to work on the machine, because the last missing link in the development chain of an automation is usually the software implementation on a programmable logic controller (PLC). The specifications from the mechanical and electrical systems shape the type of programming and also the resulting function. In most cases this is very annoying for the PLC programmer, because in the end he/she has little room for maneuver, since the hardware already exists and therefore the functions resulting from the program have to be adapted to the machine. To counteract this problem, Selmo Solution turns the tables and focuses on the all-important process. With this approach to the planning and execution of automation, the aim is to create a complete model of the plant based on a clearly defined process model. In order to facilitate cooperation, a basis for all experts is to be created. The great advantage here lies with the PLC programmer who, thanks to this approach, can transfer all the necessary functions, precisely designed for the hardware to come later, into a PLC program right at the beginning. Thus, in the future, the question will no longer be: "Was programming done correctly?", but "Was the process defined correctly at the beginning?"

If a process has to be automated, the question at the beginning is thus what the machine should do in the first place. The requirements of the system are drawn up by the company placing the order and passed on to the company taking the order. A machine is then designed and built on the basis of these specifications. When the process is created, there are often different views regarding the requirements. In the still frequently used waterfall model, the software is implemented on the basis of the completed plant. For industrial plants, this is usually realized with a programmable logic controller (PLC). The PLC program is created on the basis of a process that is not 100 percent defined by several people, and its programming flexibility can be severely limited by the existing hardware. In the end, this program may not reflect the requirements of the ordering company at all. There are some methods to bring a process into a controller. Various process modeling tools such as flow charts or flow languages are used for this purpose. Since with most tools a direct translation of a process flow into the controller is not possible and a program with a flowchart has to be created by a programmer, there are gaps. Using the Selmo method, it is possible to translate a process directly into a controller. This method creates a common basis for all parties involved: mechanical, electrical and software.

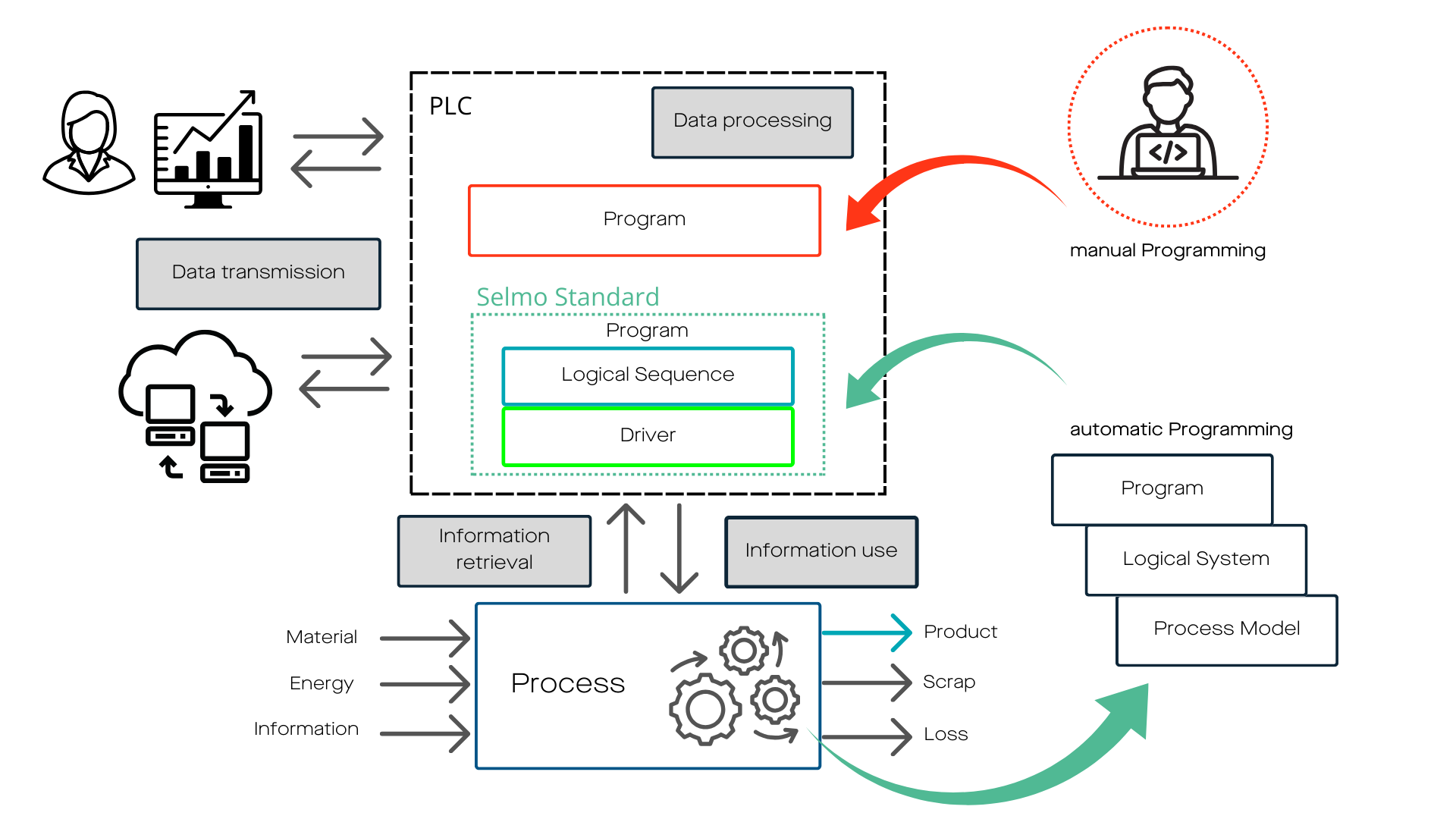

The automation of processes thus requires a control system that monitors and controls the system of mechanics and electronics through a program. In this process, data is collected by sensors and digitized before being passed on to a real-time system for information processing. Here, the data is logically processed by various algorithms and procedures and converted into information that is used to control the system. The quality of information acquisition by the sensor system is of crucial importance. A good control program must be designed for good sensor technology and adapted to its quality in order to ensure high reliability and accuracy of the control system. The transmission of data and information between different systems is called information transfer. In order to make this process safe and reliable, various technologies such as wireless communication, network protocols and Internet connections are used.

The transmitted information is used to control and regulate the system. The control is usually done by actuators such as motors, valves, pumps or other devices that are activated by signals from the control system. The result of the control is again detected by sensors and the information cycle starts again. It is important to note that the quality of the process and the information acquisition and use can limit the performance of the programs. An unstable or poorly defined process cannot be improved by programming, such as in the case of the Boeing 737 Max, where an attempt was made to fix a mechanical problem with software. Selmo Technology has developed a new method that automatically converts the logical process into a program for information processing. The process model defines the system structure, which is the sensors and actuators that provide the information from the process. The real process is controlled and monitored by the actuators and sensors so that the behavior and properties correspond to the logical process.

Through the continuous process model, which controls and monitors as a program and defines the system structure, it is possible to have a program in the PLC that detects any deviation at any time and reacts correctly. This can help minimize errors and problems and improve process efficiency.

Selmo creates a guideline that allows anyone to build the best machine by giving digital control back to users, making machines understandable to people and enabling controlled digitization and automation of production processes.

The Selmo Solution is a hardware-independent process automation methodology that makes it possible to graphically represent an industrial plant as a digital process model and translate this process directly into a controller.