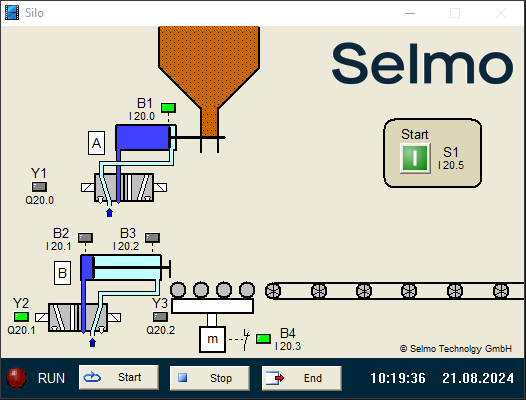

A transport container is filled from a bulk material silo by retracting an electropneumatically actuated gate valve (cylinder A). The same quantity of bulk material should always be filled with the aid of a weighing device. For this purpose, the weighing device has a binary output (B4), which assumes a logical 0 level when the desired filling quantity is reached. The gate valve now closes and after a departure time of 5 s, cylinder B pushes the container onto the roller conveyor and then returns to its starting position. In order to be able to close the silo again in the event of a power failure, cylinder A is actuated by a spring-return 5/2-way valve, while cylinder B is actuated by a two-way pulse-controlled directional control valve. The system is started via push-button S1.

Input/output assignment

The inputs and outputs of the model are assigned as follows (The designation input or output refers to the connected control unit.

refers to the connected control unit):

Input no. Name TwinCat variable name Description

1 S1 I_S1 Start button (NO contact)

2 B1 I_B1 Limit switch cylinder A extended (NO contact)

3 B2 I_B2 Limit switch cylinder B retracted (NO contact)

4 B3 I_B3 Cylinder B limit switch extended (NO contact)

5 B4 I_B4 Sensor weight reached (normally closed contact)

Output no. Name TwinCat variable name Description

1 Y1 O_Y1 Retract spring return cylinder A

2 Y2 O_Y2 Extend cylinder B

3 Y3 O_Y3 Retract cylinder B