Manual operation on machines refers to a function in which the machine is operated manually and without automatic control. In manual mode, the operator of a machine can perform certain functions and movements manually, for example, by operating levers, switches, or buttons on the machine. This allows the operator to precisely control the machine and perform certain functions that may not be automatically performed by the machine.

Manual operation can be helpful in a variety of situations, such as servicing the machine, setting up the machine for a specific task, or troubleshooting when a problem occurs. However, when an operator is working in manual mode, he or she must be especially careful because he or she is completely responsible for controlling the machine and must minimize safety hazards. In some cases, it may also be necessary to have special training or certification in manual operation of machines.

Manual operation is a user interface that functions only in manual mode and is used to control the output. Unlike the automatic mode, where the system operates automatically, manual mode allows the user to make manual interventions.

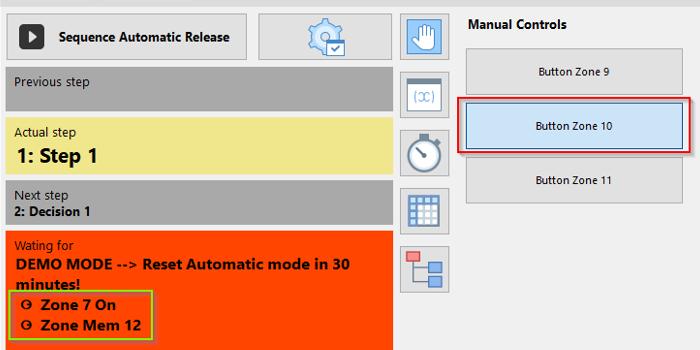

An HMI button controls the output until a feedback signal (input of the zone) becomes active. The feedback signal provides feedback to the system on whether the desired state has been achieved or changes need to be made. When the MXIC cross-lock is active, the output cannot be controlled, and the HMI displays information about the zone in which the interlock is taking place.

MXIC cross-locking is a safety function that prevents the zone from being activated unless certain conditions are met (zones x y are in a defined state). This is especially important in critical applications where the simultaneous occurrence of multiple events can lead to dangerous situations. Using the HMI button in combination with MXIC cross-locking ensures that only the desired output is activated and that potential hazards are avoided.

HMI Buttons

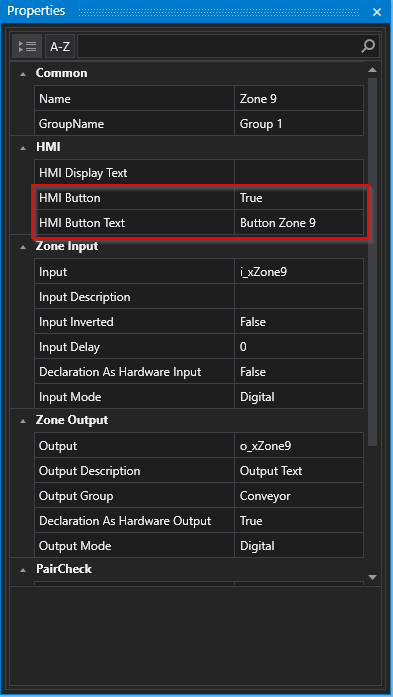

To enable HMI buttons for a specific zone (valid only for InOut and Out zones), the "HMI Button" option must be enabled in the zone properties. The HMI button label text can be customized using the "HMI Button Text" property, e.g., "Cylinder forward", "Axis 1 position 1" or "Send data to ERP".

Studio

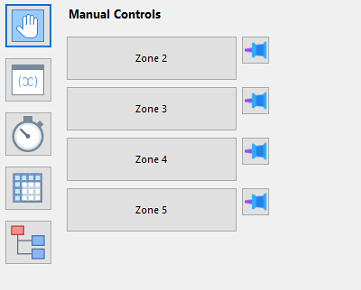

The buttons can be found in the HMI in the Sequence under Manual Controls.

The pin symbol can be used to fix the value.

HMI

MXIC

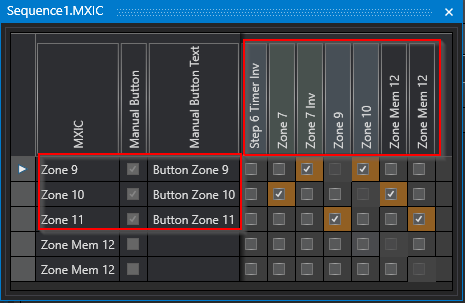

The MXIC function (Manual Cross Interlock Check) prevents operating errors in manual mode. In the left column, all manual functions are listed and compared to the corresponding zones. For each manual function, it is determined which zones (with feedback) must be active for the manual movement to be executed. This information is also used for diagnostics and operator guidance. If the operator wants to run a blocked manual movement, it will be blocked and at the same time the HMI will show why the movement cannot be executed.

Studio

HMI