There are different perspectives for Selmo. On the one hand, a machine or system is always considered from the point of view of personal safety. To this end, a risk analysis is carried out based on existing standards.

However, the focus and responsibility for process safety lies primarily with the engineers. Understanding individual processes and breaking them down into process steps is certainly one of the biggest challenges in mechanical engineering. Process reliability itself lies in the mastery of work steps or functional groups. If something is to be cut, the cutting process must be reliable. It is almost impossible to automate unstable processes or eliminate them with software.

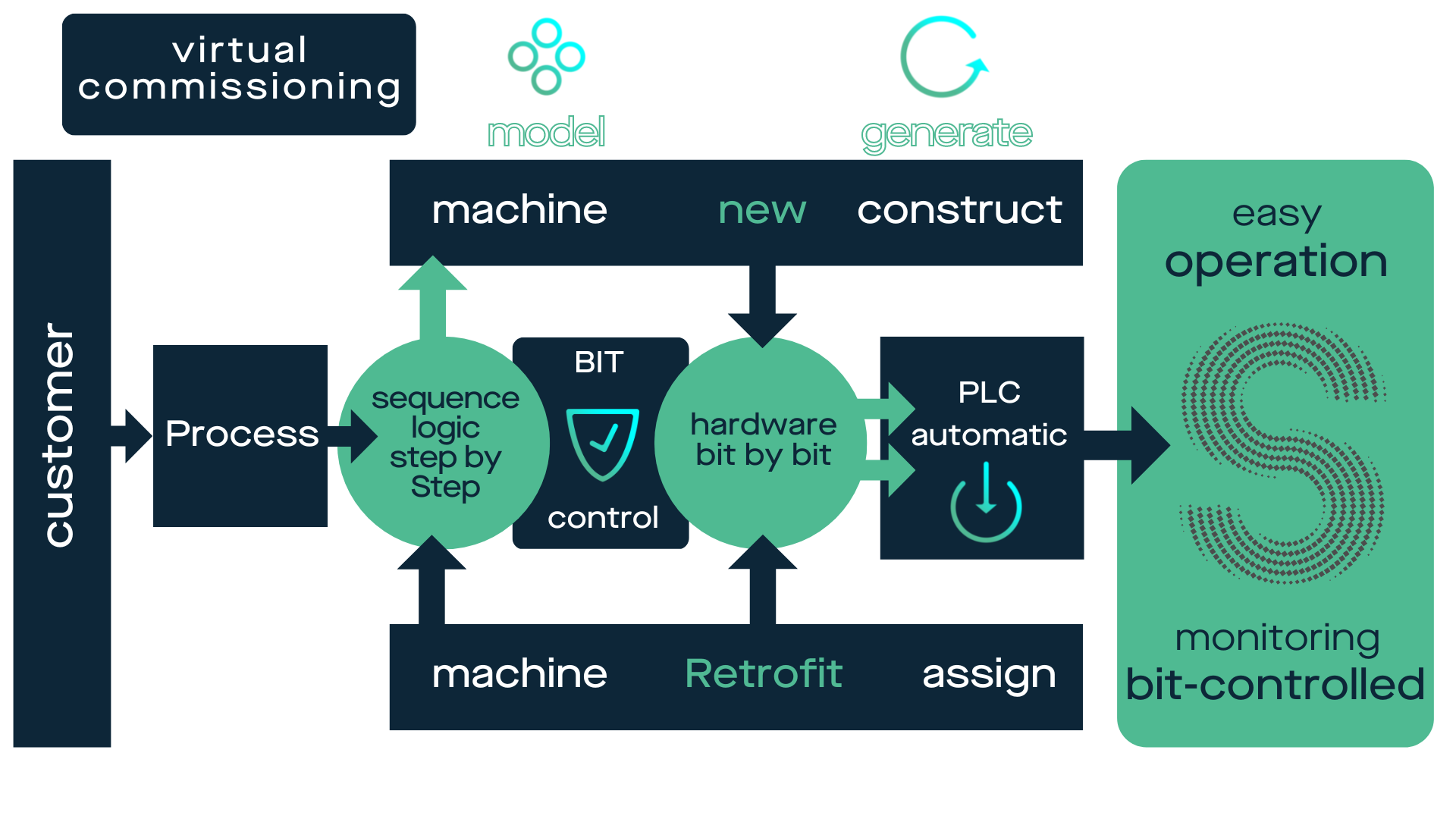

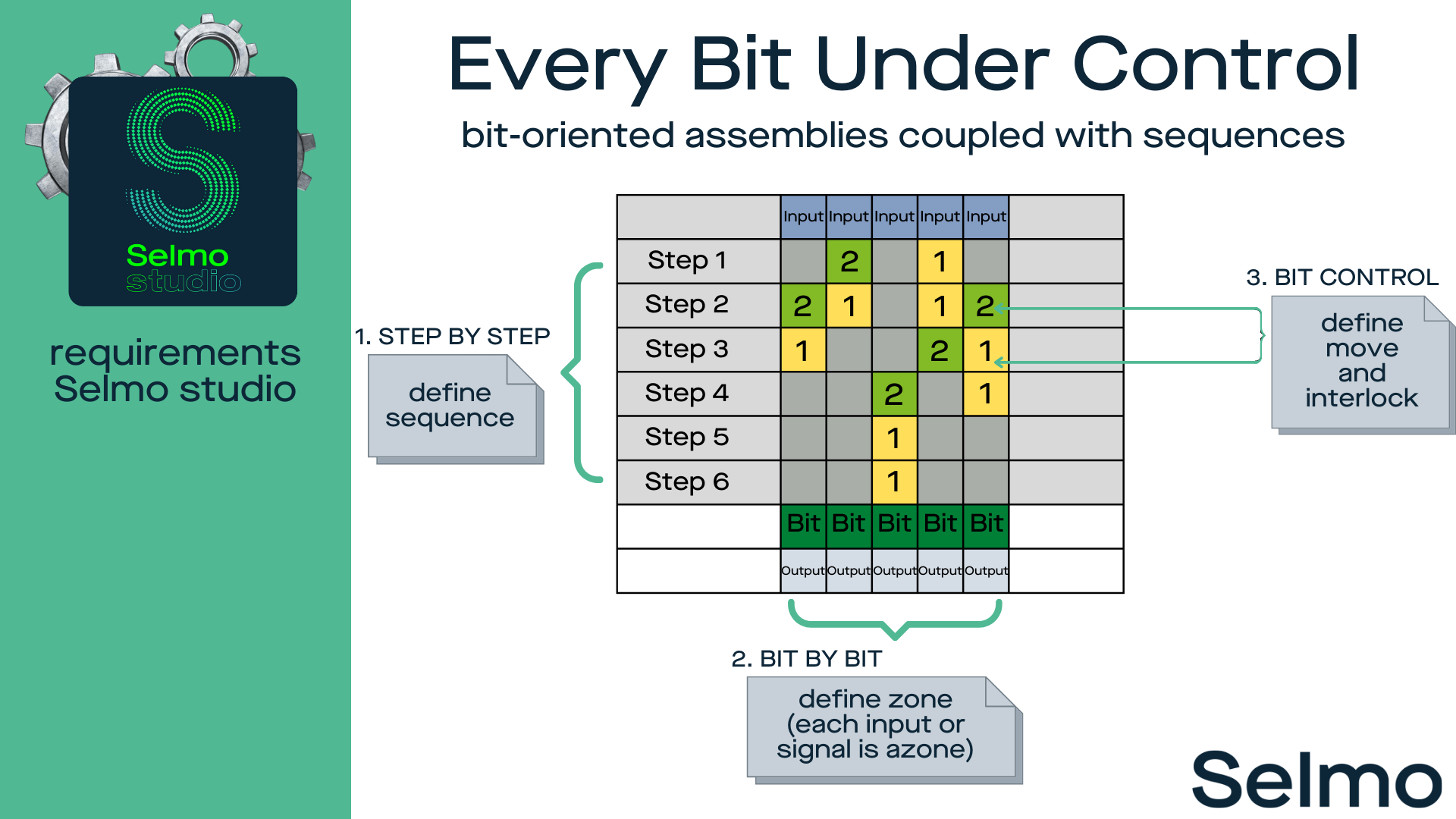

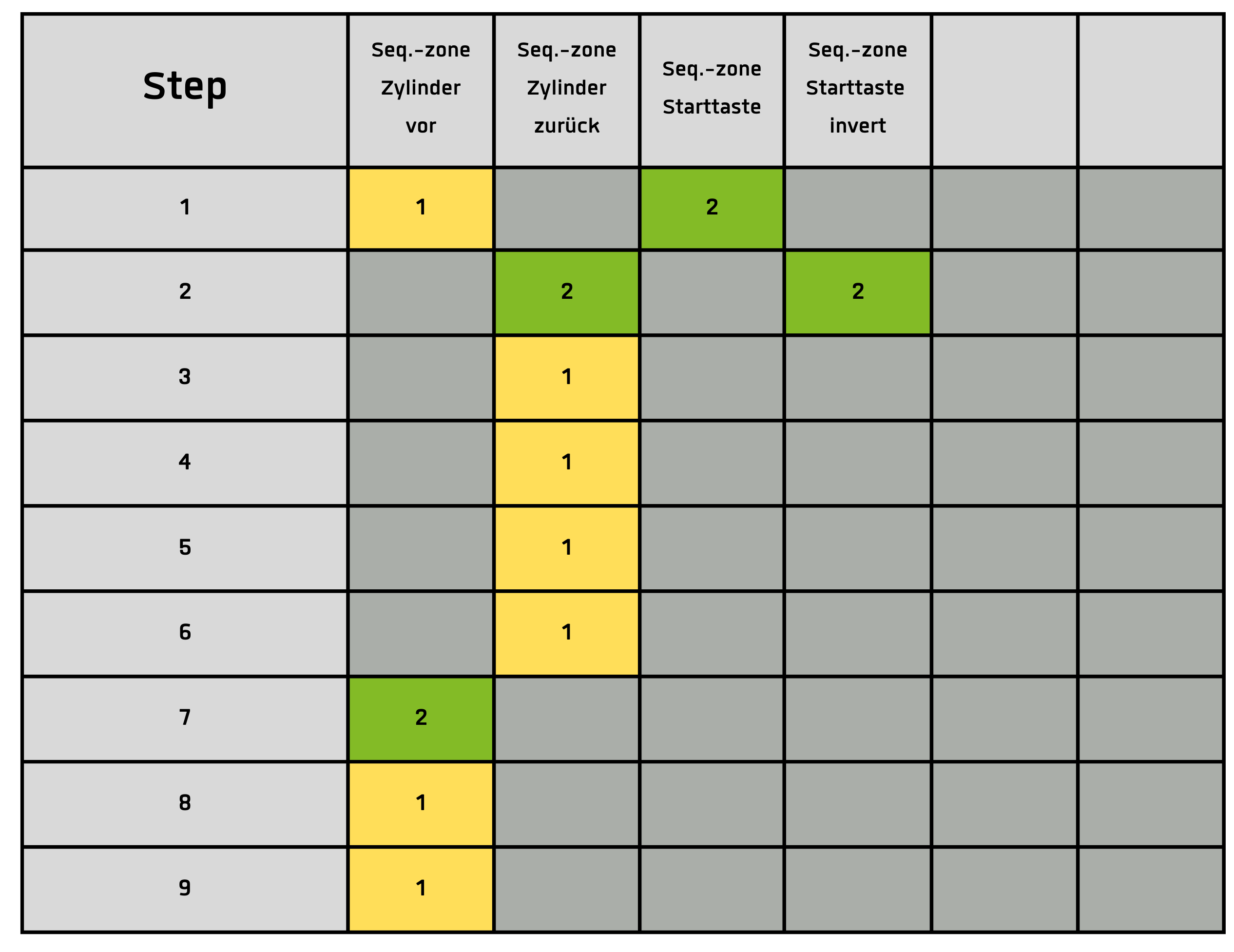

With Selmo, we can increase functional stability to almost 100 %. The function of the machine or system is defined by the process and the assemblies used. With Selmo, each process is broken down into steps. Only those steps that are defined are permitted.

Selmo assumes a basic position. A sequential sequence of steps starts from this position. Each step has a defined next step. In each step, the entire system of the step chain (sequence) is monitored for correctness. We define this as monitoring. Every single bit that is processed in the SEQUENCE is checked for its correct value. This results in a 100 % defined system. Each step change takes place if no bit contradicts it. This means that a text can be displayed for each bit to inform the operator.

This leads to absolute operator safety. Selmo is structured in such a way that every single bit in the system is displayed. Behind each bit is a signal, a module evaluation (e.g. temperature at a switching point - discrete signal) or an HMI signal (e.g. operator button).

For the operability of a machine, it is becoming increasingly important to create standardized structures so that operators can work quickly and easily on different machines. When purchasing machines, it is important to ensure that this requirement is clearly defined. If the user interface has a uniform structure, a new machine can be integrated quickly with little training effort. The standardized structure also defines the interfaces to other machines. The standardized connection to the business processes is particularly important. Basically, different disciplines or experts are needed to bring the data from the customer to production and then to the machine using such interfaces. Conversely, a lot of data has to be returned from the machine to the customer by means of recordings. A broader perspective is the maintenance of machines. Software that is guaranteed to have the same structure is easier to understand. It is easily interchangeable. Structures that are easy to learn lead to a high level of software maturity.

The clear separation of logic and function in Selmo makes it easy to replace modules. As in the office sector when installing a new printer, Selmo eliminates the need for an operating system programmer. There is also no need to replace an operating system. Selmo therefore wants to introduce the PlugnPlay principle to mechanical engineering.

Selmo's driver concept is based on the separation of the executing function from the process sequence. The logical sequence does not change when a drive is to be replaced. The drive must be easy to replace mechanically, electrically and in terms of software - even if it is not the same drive. The flexibility in Selmo machines is provided by the driver structure. Mechanics and electrics can be exchanged worldwide by experts. The software achieves the same level of maturity with Selmo and is specifically exchanged by replacing the function in the form of drivers.

The aim is to

•to have the drivers for Selmo created by Selmo users.

•Each function is tested and certified only once.

This means that a driver can be managed as an article in an ERP system and the development costs can be refinanced through usage.

With Selmo, you only buy the software that is new and use your existing drivers or buy them cheaply via Selmo.

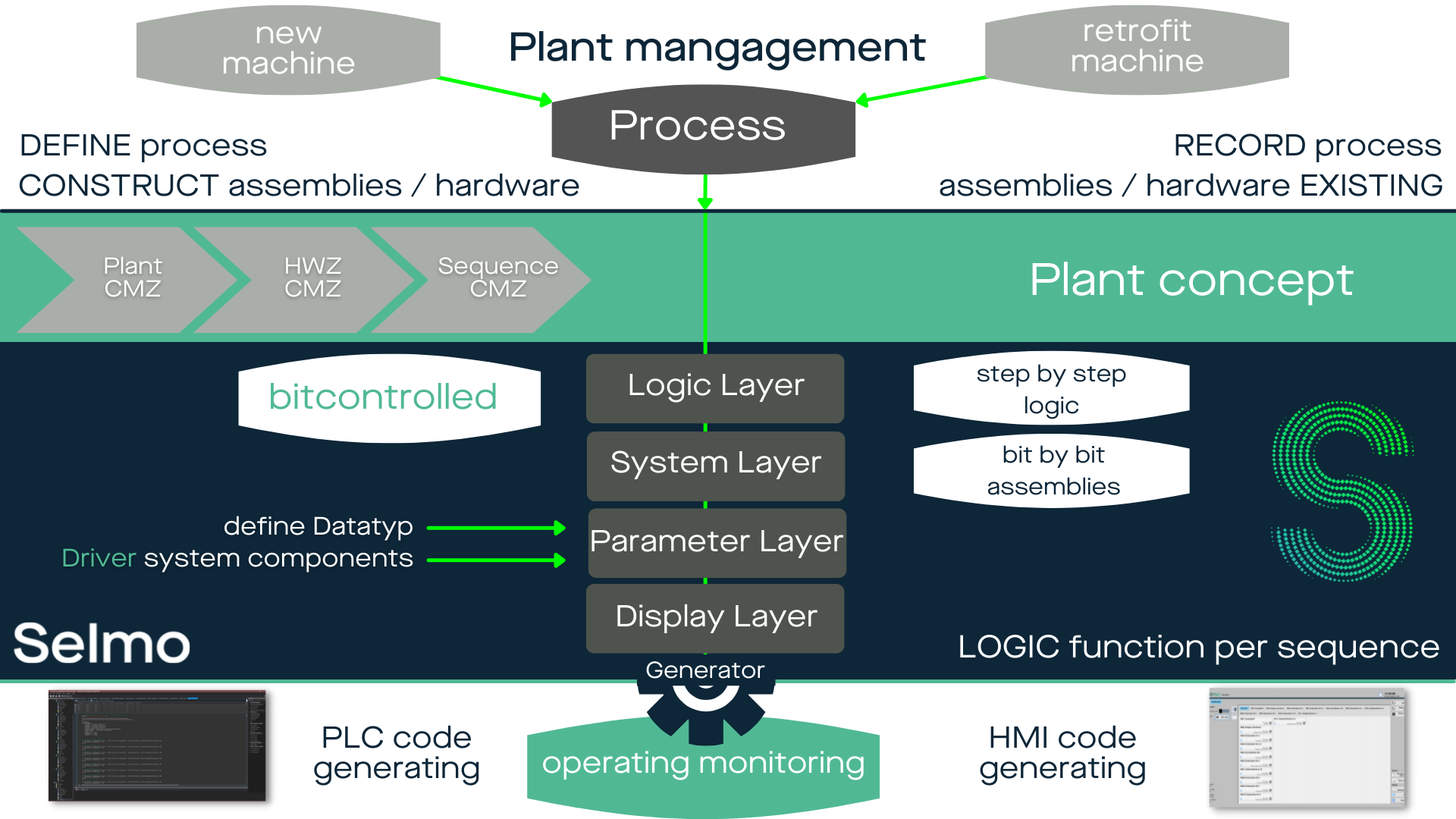

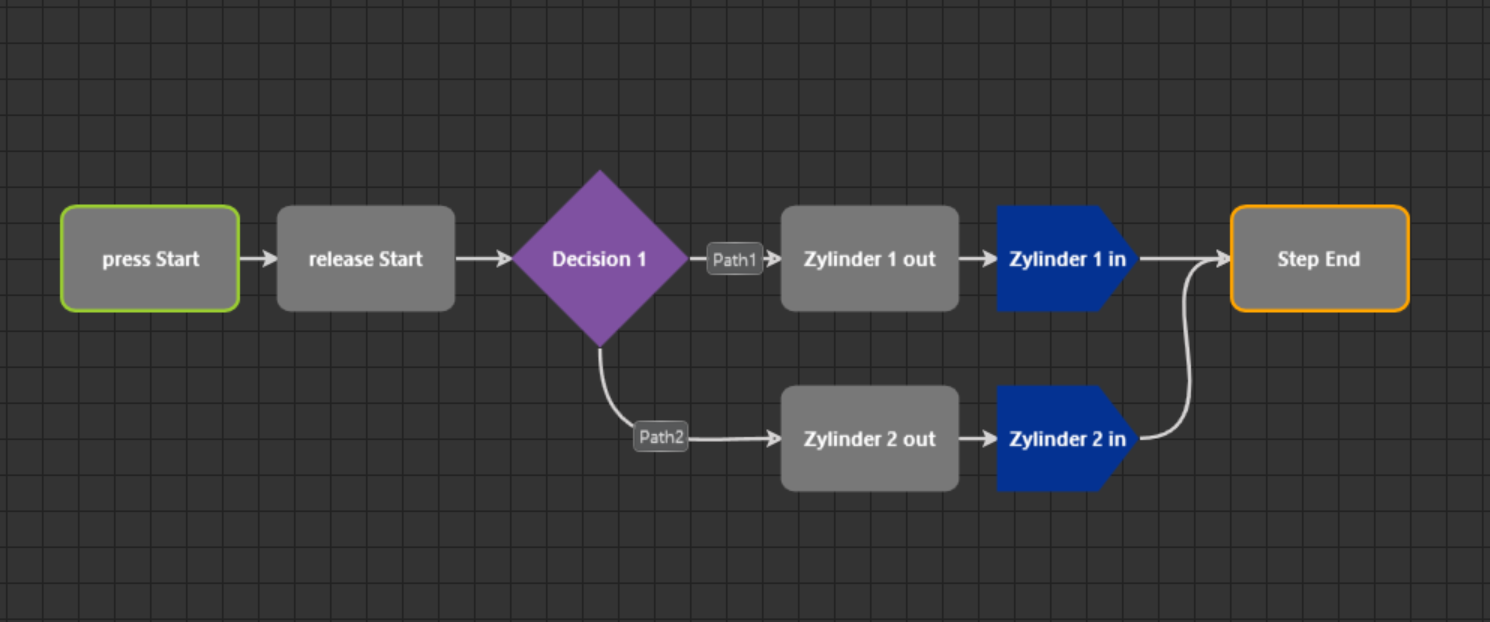

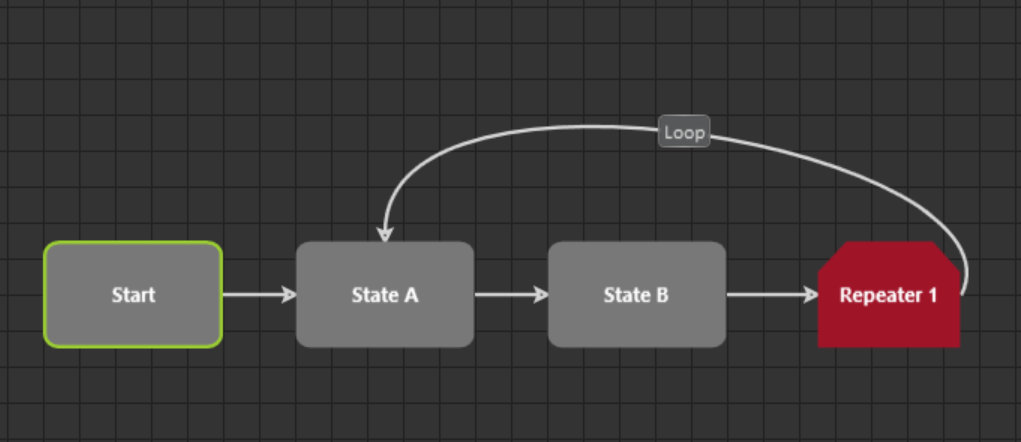

Selmo is changing the procurement process for machines. Selmo offers an innovative standard for machine software and redefines its development process. The manufacturing process is placed at the center of new machines. All experts define the requirements via the process. The process is divided into logical sequences. Four elements are available for this purpose:

1.State (Step): The simple step-by-step element. Each step has a clear next step and a name.

2.Timer (time): In process modeling, steps are applicable for a specific time.

3.Loop: The element summarizes steps and repeats them as often as determined.

4.Decision: The element allows a step to have two subsequent steps depending on the condition.

This element can be used to build nests. Basically, the logical process is a deterministic, finite automaton with a defined start point and a defined end point. After reaching the end point, the process starts again at the start point. This is repeated until a condition stops the process or an error occurs.

The system is defined in the system layer, in which the modules required for the process are placed bit by bit. There are three types of zones that are inserted for each bit:

Zone type 1: Input only without output. This zone has its feedback from the operator - from a sensor that queries a part

Zone type 2: Output and input as feedback. An output is set in a certain state and feedback is expected.

Zone type 3: Output only without feedback. This also occurs when a lamp is switched or a drive is switched across several states.

Each zone with an output also has a button on the HMI by definition of Selmo. It is also defined that grouped zones of type 2 always have a pair check. This means that only one signal may be present in the group at any one time. In the case of a pneumatic cylinder, for example, there can only be an error message if the rear end position and the front end position are present at the same time.

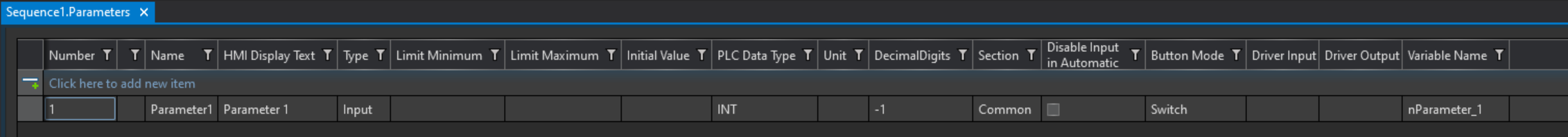

The Selmo standard has a parameter layer. This is where the input and output data points are defined. This makes the process flexible and customizable. Example: A saw that moves to a position and cuts where the position is reached. This is always the same process, but the position can be changed. Or a drive with different speeds. All data in and out of the machine can be easily defined.

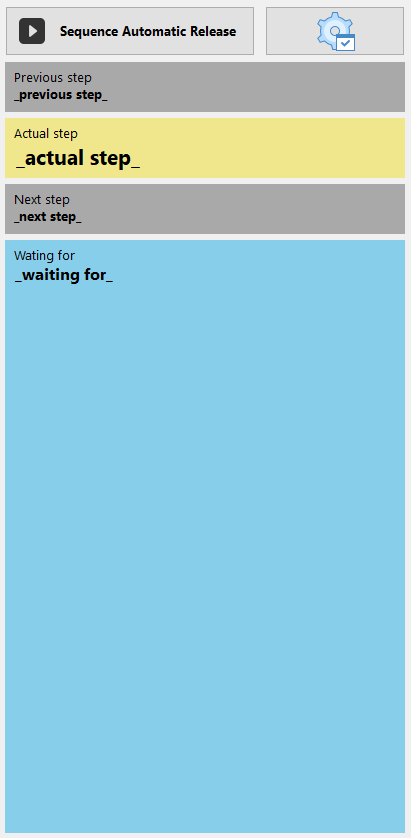

The display layer in Selmo has a standardized SEQUENCEControl. Other images on the HMI can be easily created within the framework of the data points in the model.