Alarm handling refers to the process of handling alarms or alerts that occur in a system. It includes the identification, capture, prioritization, processing, and resolution of alarm conditions.

Alarm handling includes the following steps:

1.Alarm detection: the system detects a deviation from normal operating conditions and generates an alarm.

2.Alarm display: The alarm is displayed on a user interface or monitoring system. This can be in the form of visual cues, audible signals, or messages.

3.Alarm Prioritization: Alarms are prioritized by their urgency or severity to determine which alarms need to be addressed first.

4.Alarm notification: The alarm management system notifies relevant individuals or teams when an alarm occurs. This can be done through email notifications, SMS messages, or other means of communication.

5.Alarm analysis: the cause of the alarm is investigated to determine what caused the problem. This may require a manual review of systems, logs, or sensor data.

6.Alarm Response: based on the analysis, an appropriate response is initiated to resolve the problem or minimize the impact. This may include taking corrective action, initiating maintenance, or calling in skilled personnel.

7.Alarm tracking and documentation: the entire alarm handling process is documented, including the timing of alarms, actions taken, and results.

Effective alarm handling enables early detection of potential problems, rapid response, and minimization of operational disruptions to ensure smooth system operation.

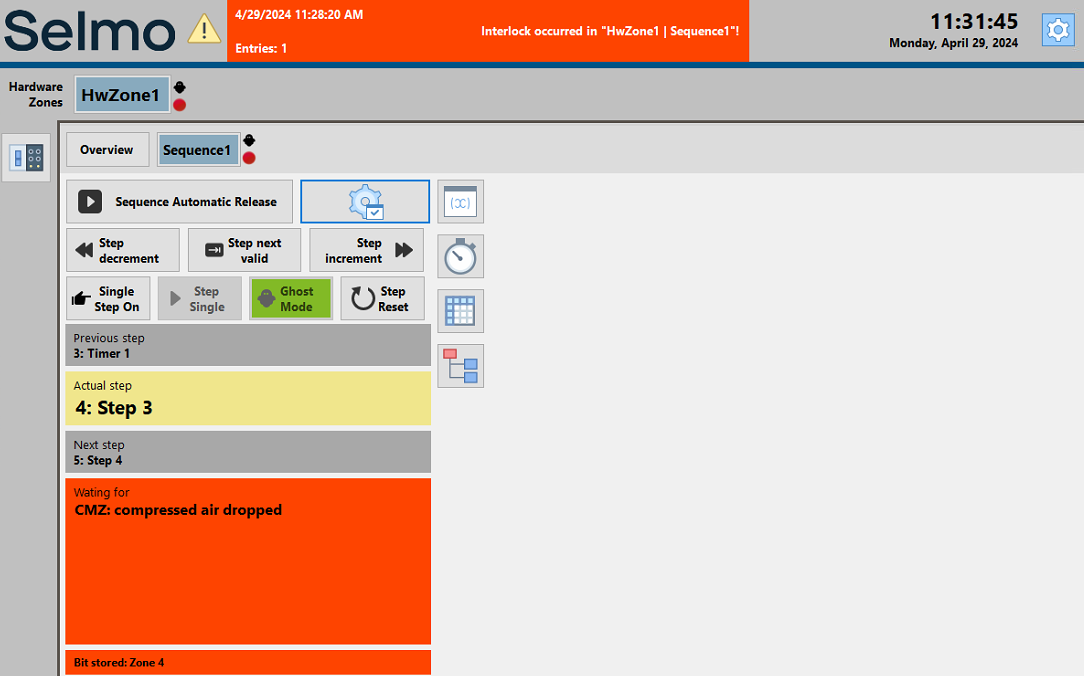

When an alarm occurs in the form of a CMZ (Constantly Monitored Zone) or TCMZ (Total Constantly Monitored Zone), this is indicated in the alarm bar and in the "Waiting for" box of the Sequence. At the same time, the background color of the "Waiting for" indicator changes to red, and a red light is activated in the Sequence Overview to signal the fault. In any case, faults must be confirmed with a "Reset" before automatic operation can be resumed.

HMI

Warnings, on the other hand, are only displayed in the alarm bar, with an orange background. These warnings have no influence on automatic operation.

HMI

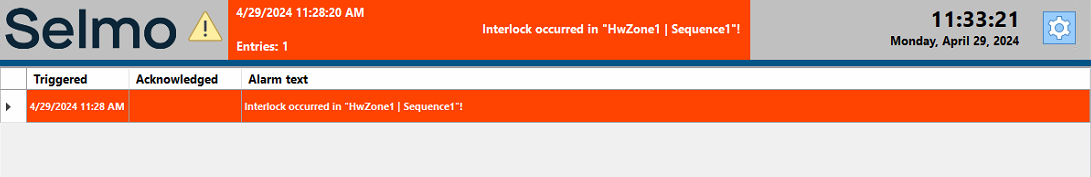

Double-clicking on the alarm bar opens the alarm overview on the HMI. In the alarm list, both faults and warnings are displayed as long as they are active. All relevant information on the alarm signals, such as type of fault or warning, time of occurrence and any assigned information, is listed here. The alarm list provides a clear display and tracking of all current alarm conditions, so that operating personnel are quickly informed of the status and can take appropriate action if necessary.

HMI

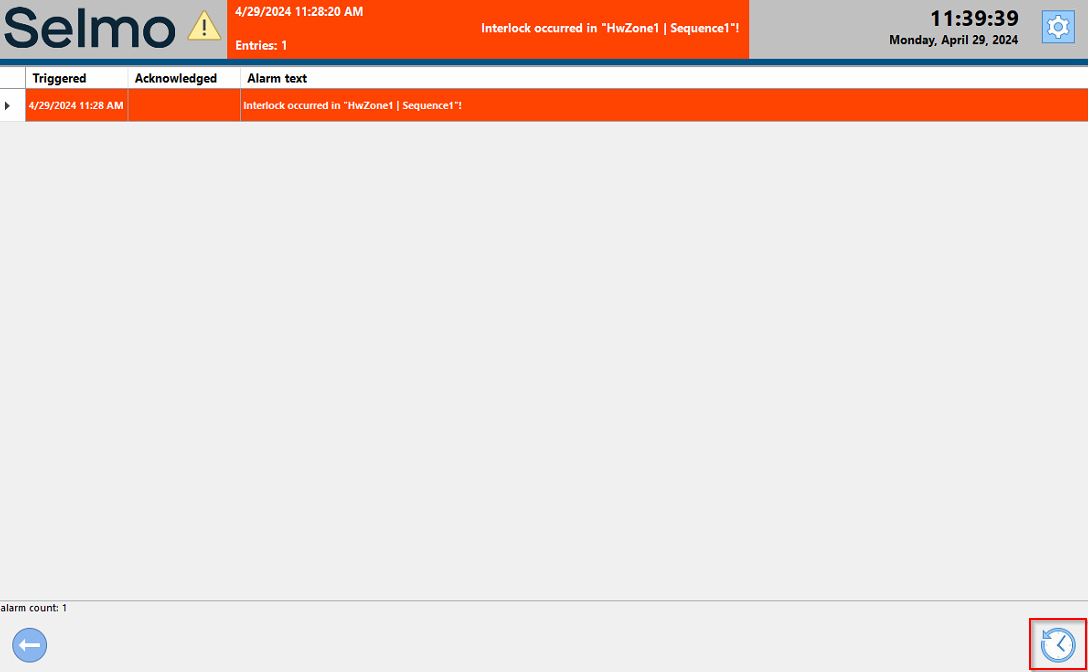

In the alarm history, the alarms that have occurred are logged and stored with a time stamp. All past alarm events are recorded and sorted chronologically. In this way, the alarm history enables subsequent analysis and tracing of past alarm conditions. Storing alarms with time stamps helps identify trends, detect recurring problems, and conduct follow-up investigations. Alarm history thus serves as a valuable tool for monitoring and evaluating system performance and assists in the continuous improvement of plant or machine efficiency.

HMI

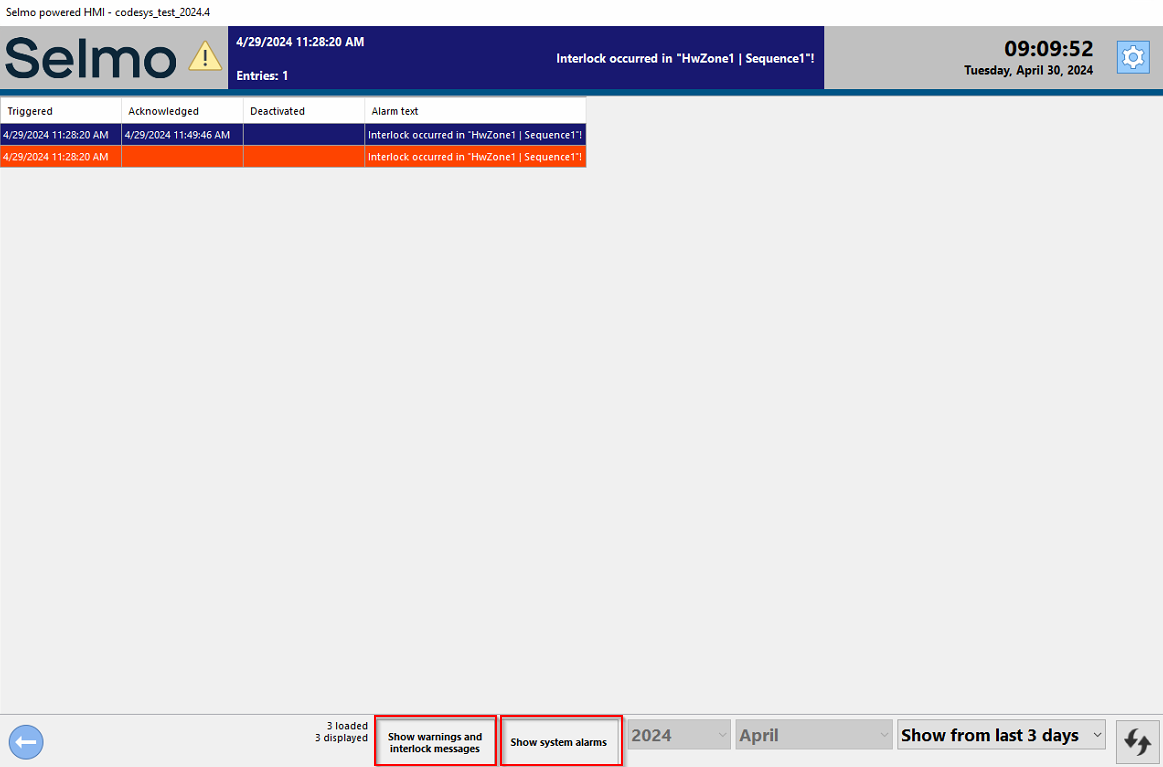

In order to display warnings and interlocks or system faults in addition to the TCMZ and CMZ, it is necessary to enable the "Show warning and interlock messages" and or "Show system alarms" option. By enabling this option, all warnings, and interlocks and or system errors will be displayed in the user interface.

HMI

It is possible to retrieve alarms by year, month or for the last 3, 7 or 30 days. This allows operators to target past alarm events and select specific time periods to analyze alarm patterns, trends, or special events. The flexible retrieval of alarms by different time intervals allows detailed examination of alarm history and facilitates fault diagnosis, performance analysis and continuous system improvement.

HMI