In PLC programs, the inputs are read in each cycle and logically linked with the logic of the program. The result is then written to the outputs. This happens in every cycle and a defined sequence can be programmed via the PLC.

There are two types of programs: logic control and sequence control.

With logic control, inputs are written directly and logically to the outputs. The combinatorial logic results in an output or a logical variable.

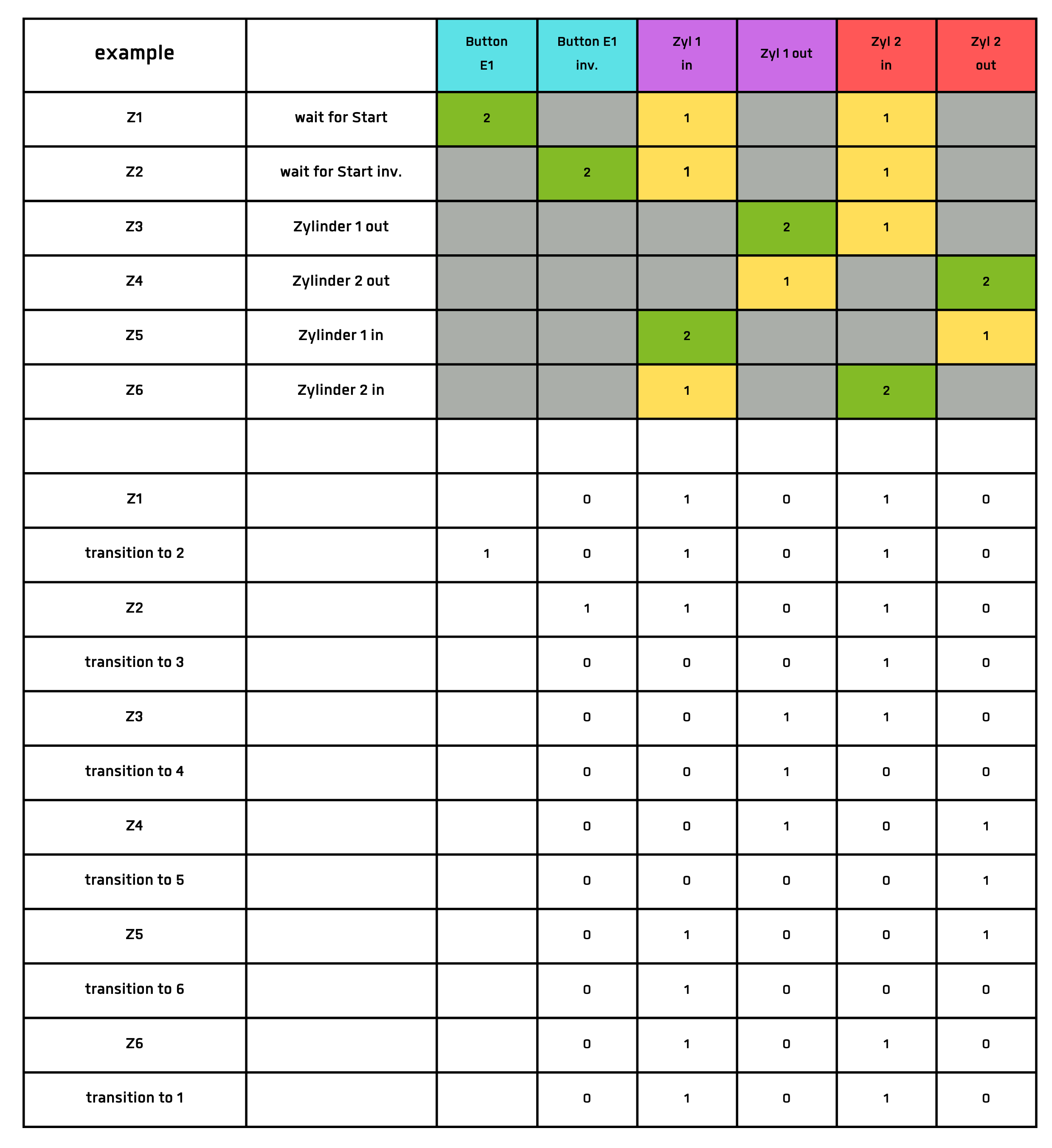

With sequence controls, states and state transitions are defined. In this way, inputs are logically evaluated depending on the status of the outputs. One advantage of sequence controls is that defined states and state transitions are available.

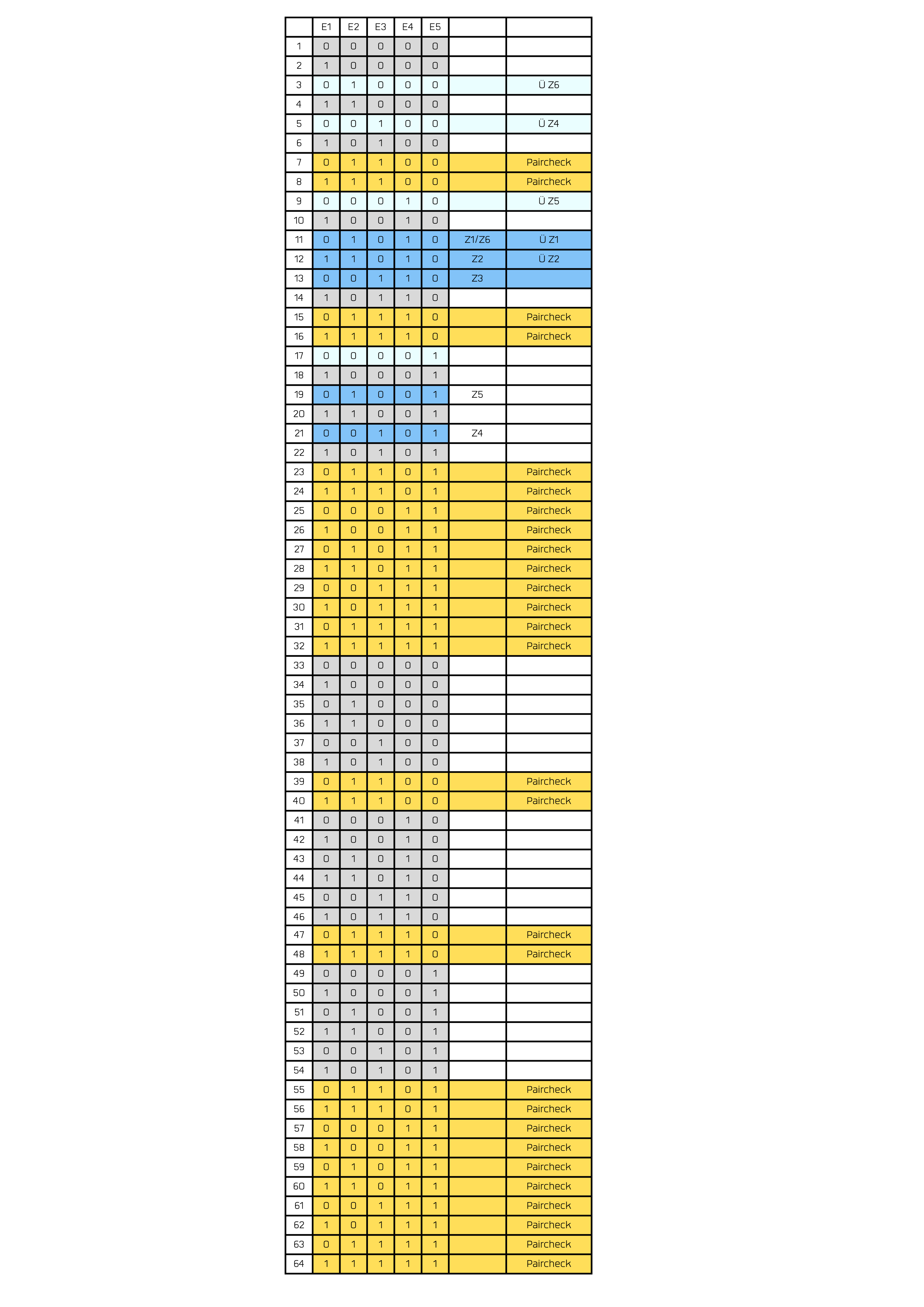

The programmer must now program the sequence of states and state transitions. However, he must also anticipate and program the states that are not permitted and the state transitions that are not permitted. This creates a program for a sequence, states, forbidden states and state transitions.

In each state, all inputs must be checked to see whether the input image is permitted and matches the state. If the input image matches the advance condition, the state changes to the next state. The outputs are switched with the advance switching and movements or signal changes are reflected in the input image. In this way, all actions are executed with a defined input image.

The sequence is basically specified by the process. The mechanical and electrical systems define the assemblies with signals and actuators from the specifications, which are mapped in the design using a circuit diagram.

The programmer must then transfer this information on the sequence with the inputs and outputs into a program. This is a manual process and it basically depends on the programmer how good the software quality is.

The process parameters that are important for the application are defined later via the requirements of the HMI. These must then be linked to the process.

Mechanics, electrical engineering and software usually work independently of each other and are not very well coordinated until commissioning. The planned components come together during commissioning. And this is often where the first complications arise. This delays commissioning and implementation. In most cases, the problem has to be solved via the software.

With Selmo, a requirements analysis is carried out right at the start and mapped in the form of a model. The mechanical and electrical requirements are derived from this model. The requirements for the software, which describes the logic of the process, are generated directly into an executable PLC program. For the software, it is only necessary to program the non-existent functions such as drivers and interfaces from the mechanical components. Thanks to the common model for all experts, the functions and implementations come together ideally at the time of commissioning. As programming is carried out completely automatically by Selmo, the structure and logical processes are 100% coordinated with the model requirements.

The software required by the mechanical and electrical systems to operate a machine is generated automatically using a new type of algorithm. The software is particularly characterized by the fact that it monitors all signals and states at all times. An inhuman amount of programming would be required to generate software of such high quality.

Selmo monitors all inputs in every state and reacts to any deviation. This means that the model is constantly compared with the real machine. In the event of deviations, the software reacts with a fault and provides detailed information about the cause of the fault. In individual programming, it takes a great deal of effort to develop a program that completely describes a complicated system such as a plant.

Selmo automatically generates a program that completely describes a complex system such as an installation.

•fast

•error-free

•simple

•safe

Selmo solves the complexity problem in PLC programming with the help of automatic intelligence.

Example