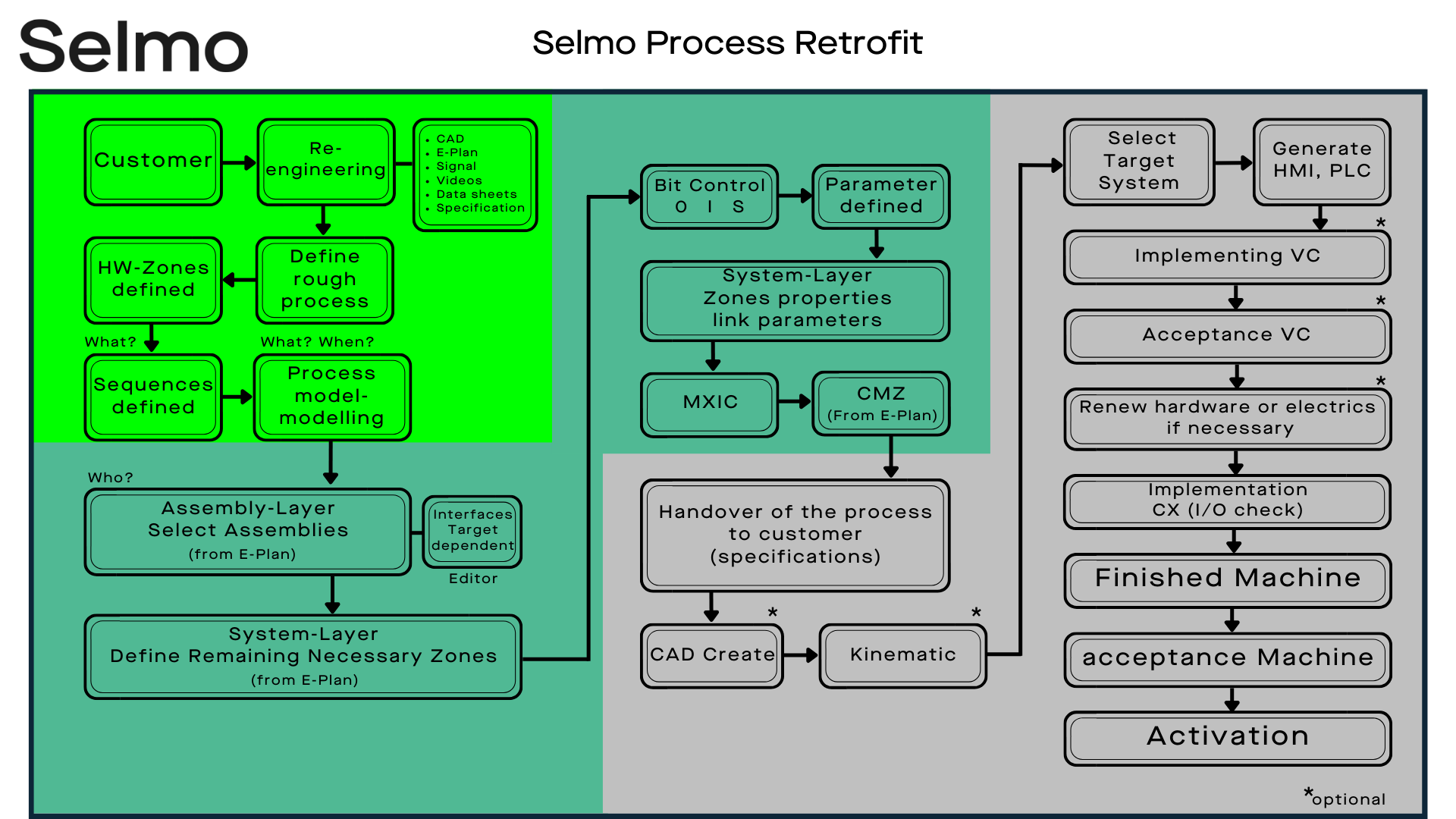

Retrofit or software for already designed machine:

If the input signals and output signals are already defined, the inputs are assigned to function groups. The function groups for a system are defined in the Selmo structure.

System as a whole: All inputs that are relevant for the entire system are assigned here. The operating modes and the monitoring of system-relevant parts take place at this level. For example, "system on/off, emergency stop active, main fuses, power supply" etc. are usually meant here. These signals are assigned to the system part. A matrix of bits, used for display and evaluation in the logic, is assigned. If no bit is set in this matrix, the system section is OK.

The system also consists of one or more hardware areas.

The hardware area is an area that divides the system into sub-areas. For example, the protection areas, access guarding, area-related voltage supplies etc. are assigned to this area. These signals are assigned to the hardware area. A matrix of bits, which is used for display and evaluation in logic, is assigned. If no bit is set in this matrix, the hardware area is OK and the area can be operated according to the operating mode.

The hardware area consists of one or more stations.

Stations are units that are always logically controlled by a step chain. The station has a matrix of bits that is assigned to station-related signals. There are two types of bits. Those that are monitored step-independently and those that are monitored step-related. The step-independent bits are, for example, circuit breaker signals or air monitoring. These are set directly in the matrix and shown on the display in the step chain. The step-related bits are set and displayed depending on the step and manual operation.

In this way, all real inputs in the system are assigned to the corresponding functional areas. Each function area has a clear function and reacts to the bits that are set in the matrix.

If no bit is set in the matrix of the system, this means "Everything is ok". Only then can the subordinate unit function. If a bit is set, this is displayed in plain text and the user interface informs the operator bit by bit.

If no bit is set in the hardware area, the subordinate stations can function at all. If a bit is set, this is displayed in plain text and the user interface informs the operator bit by bit.

If no bit is set in the station, the operating window is displayed in blue and it is possible to switch to automatic mode. If a bit is set by a step-independent bit, no manual movement or action can be executed and it is not possible to switch to automatic mode. If a step-related bit is set, a suitable step can be searched for using the step increment function - or the necessary signals can be set using manual actions. The real signals required for the logical sequence are processed in the station.

At this level, Selmo uses zones to connect the bits that are given bit-oriented from assemblies such as cylinders, buttons etc. with the defined steps. If modules are required that react to HMI inputs or are available as analogue values, these are discretized by driver functions. This ensures that each signal is defined as a bit of a zone. A cylinder, for example, has two signals. These are also checked as a pair check, as the two signals must never be switched at the same time. A simple bit such as a button is always checked for the status 0 and 1 - exactly when it should be 1 and when it should be 0.