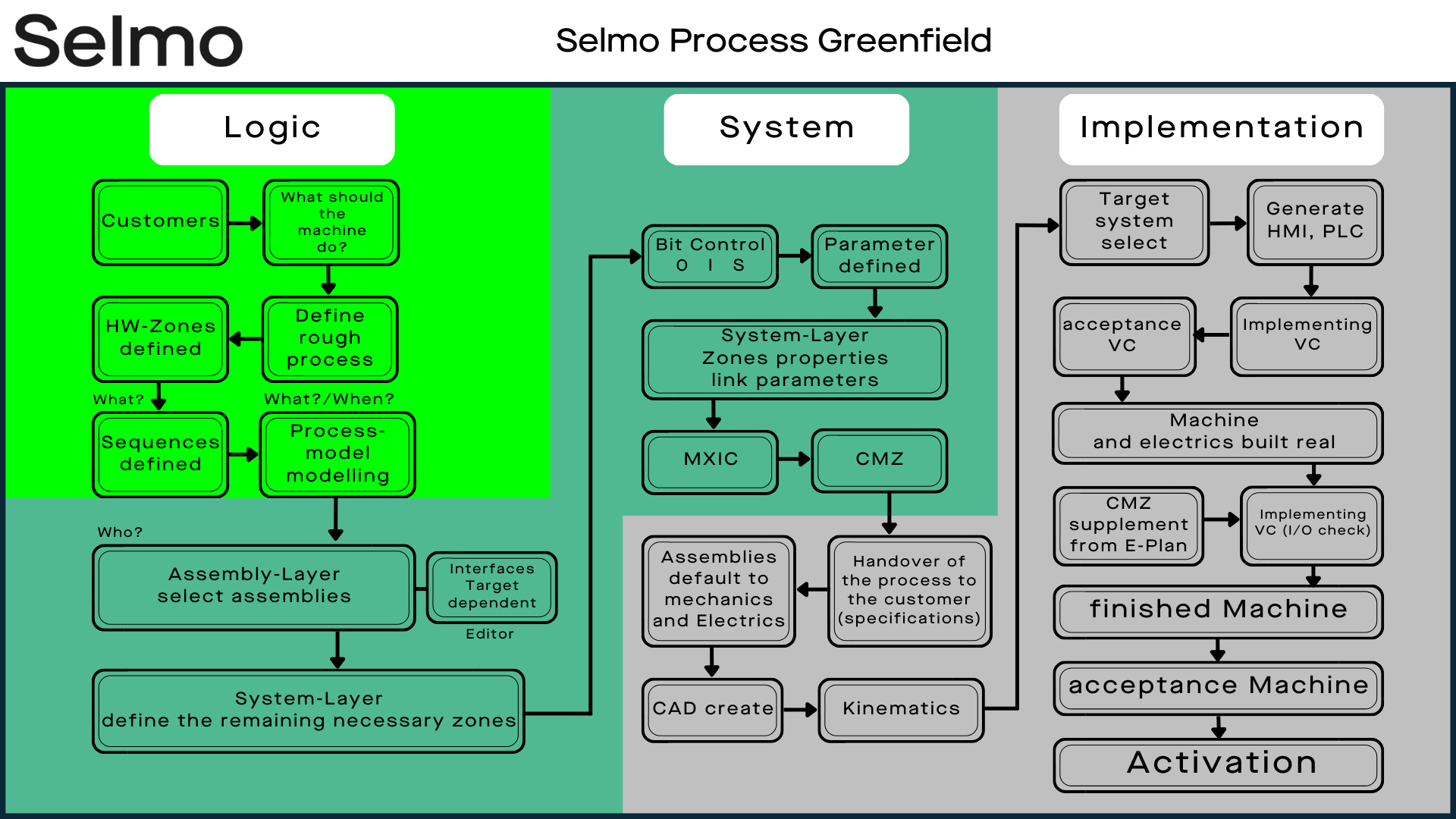

Selmo method for a new system without construction:

The real signals and the assemblies are derived from the process. This makes it possible to simply insert known assemblies. For example, a roller conveyor can be selected directly as a mechantronic assembly in the process. This results in the inputs and outputs as well as the logic sequences. These can be inserted as templates.

The logic sequence is described as in Retrofit. The bit-oriented assemblies provide the necessary signals. The real signals can be given as information to both the electrical design and the mechanical design. If a movement is required, an actuator is defined. This actuator has defined inputs and outputs and requires parameters for the software. In this way, the zone can be used to generate a specification for assemblies. If there is a zone as a bit that is not an HMI or real bit, it is clear that a bit must be generated here. This is done by a driver function. All function-related signals are now defined from the process and assigned to the system areas mentioned above. All experts thus have a common picture and understanding of the process. The machine or system is created from this.

The drivers are assigned and managed from a database in the zone. The drivers represent the interface to the HMI, production data acquisition and function. The parameters from defined drivers are automatically assigned and generated by Selmo.

Each bit can represent the information on the assembly, E-plan, installation instructions, ERP article, etc. This provides the necessary descriptions and definitions. In this way, we generate a digital data twin of the system or machine from our Selmo model.